This document serves as a comprehensive introduction to True Care Medical Pharma company, outlining our operational structure, quality management system, and distribution capabilities, intended for review by potential clients and partners.

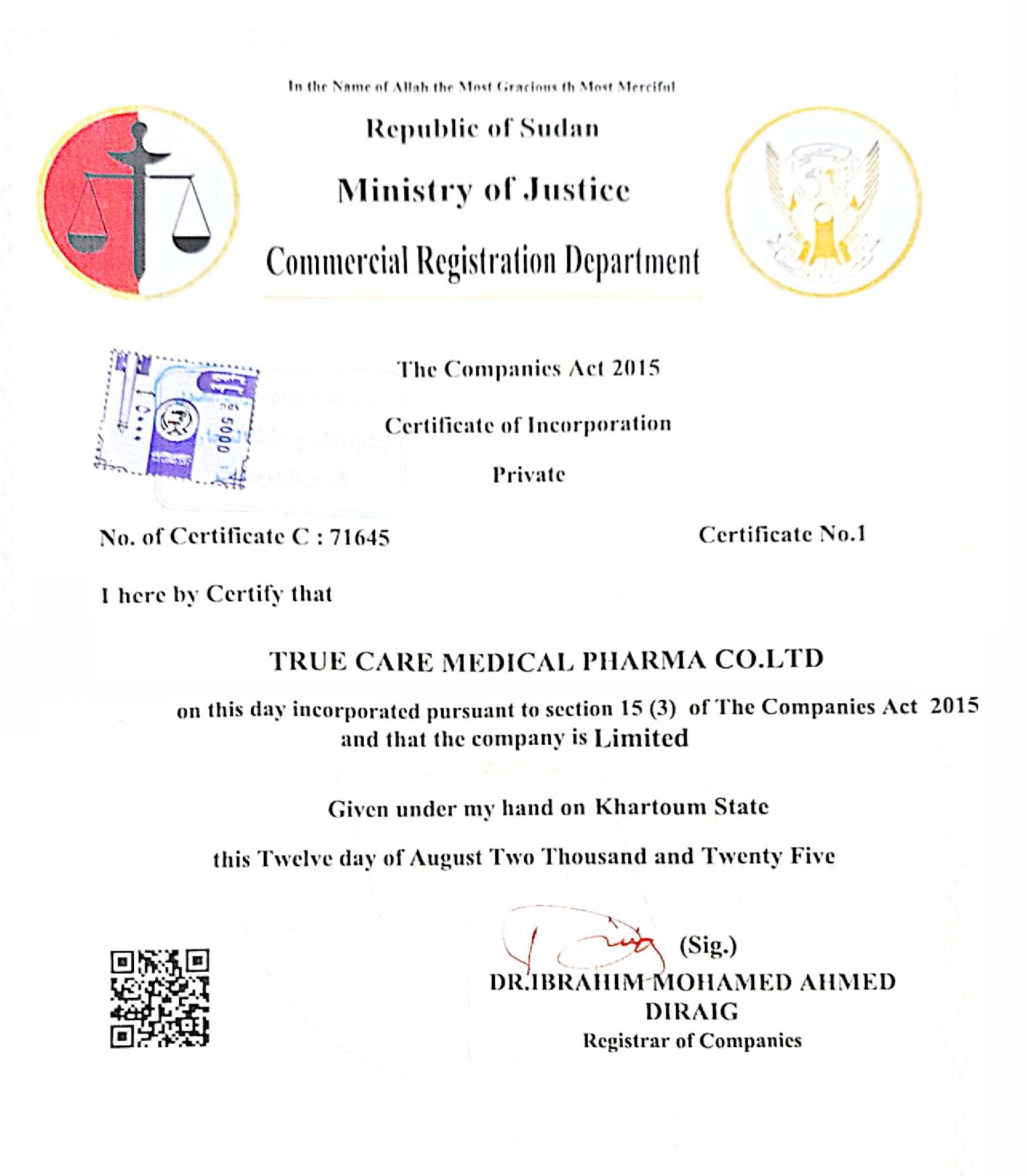

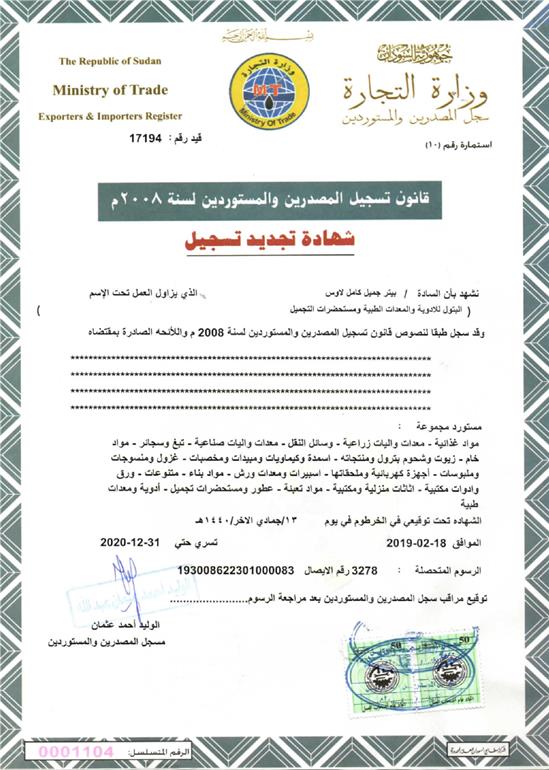

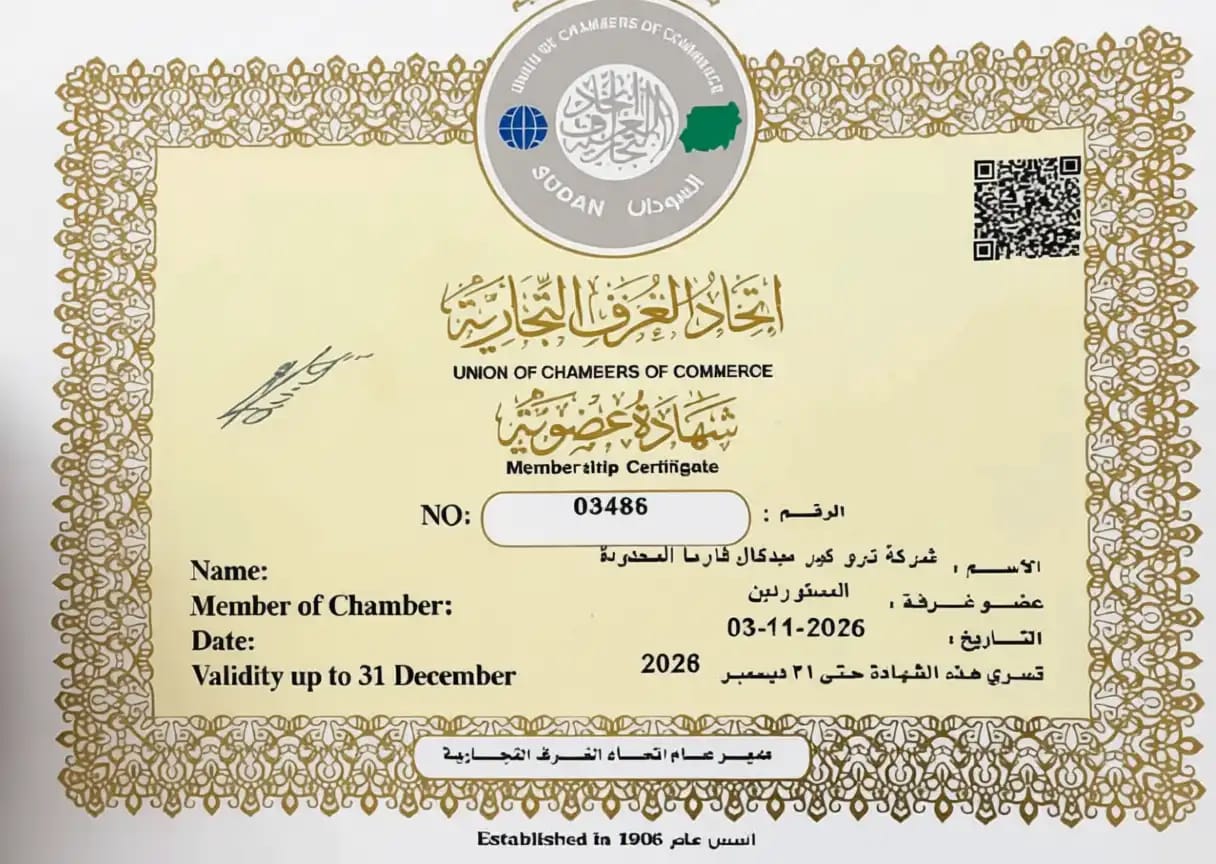

Regulatory Authorization

Union of Chambers of Commerce Membership No:(03486)

Authorized Pharmaceutical Distribution Activities

Wholesale Distribution of Human and/or Veterinary medicinal products, including:

•Storage

•Handling

•Logistics/Transportation

•Import/Export.

Other Activities

•Quality Control/Assurance Activities

•Administrative Functions

•Marketing and sales Department

2. Quality Management System (QMS) of the Company

The Company operates a robust Quality Management System (QMS) designed to ensure that all activities comply with national and international Good Distribution Practices (GDP) and/or Good Manufacturing Practices (GMP), and regulatory requirements, ensuring product quality and patient safety.

Quality Management System of the Manufacturer

Our QMS is fully documented, continuously monitored, and actively managed by the Quality Assurance (QA) department. It encompasses the organizational structure, procedures, processes, and resources necessary for effective quality management, supported by top management commitment.

Release Procedure of Finished Products

The release of medicinal products for distribution is a critical, controlled process executed by the Qualified Person (QP) or authorized personnel.

•For Imported Products: The QP verifies that the product has been manufactured and tested in accordance with GMP and the marketing authorization (MA) requirements.

Management of Suppliers and Contractors

We maintain a strict qualification process for all suppliers (e.g., manufacturers, wholesalers) and contractors (e.g., transporters, testing labs, maintenance services).

•Supplier Qualification: Suppliers of medicinal products are assessed based on their regulatory compliance (licenses, GDP/GMP status) and quality history. Formal Quality Agreements are established where required.

•Contractor Qualification: Contractors providing services that may impact product quality or compliance are formally evaluated, selected, and monitored. Services are defined in a written contract or Quality Agreement.

•Periodic Review: Both suppliers and contractors are subject to regular performance and quality reviews, including audits where appropriate, to ensure sustained compliance.

Quality Risk Management (QRM)

QRM is an integral part of our QMS. It is a systematic process for the assessment, control, communication, and review of quality risks across all operations.

•Process: QRM tools are varied and used proactively to identify potential risks (e.g., storage deviations, documentation errors, unauthorized distribution).

•Control: Identified risks are mitigated through appropriate control measures, documented in the QMS (e.g., SOPs, equipment calibration, personnel training).

•Monitoring: The effectiveness of risk control measures is regularly reviewed and updated.

Product Quality Auditing (PQA)

We conduct periodic, systematic Product Quality Auditing (PQA) to verify the consistency of the process, the appropriateness of current specifications, and to identify any trends that may suggest the need for process improvements or revalidation.

Personnel

Our personnel are our most valuable asset and are managed to ensure they possess the necessary qualifications, experience, and training to perform their duties correctly.

•Organizational Structure: A clear organizational chart defines the reporting lines and responsibilities, especially for key roles.

•Key Personnel: The Responsible Person (RP), as designated by the regulatory authority, is permanently and continuously available to carry out their responsibilities, ensuring that the QMS is implemented and maintained.

•Training: All staff receive mandatory initial and ongoing training relevant to their roles, including training on GDP, QMS procedures, product handling, and health/safety requirements. Training effectiveness is assessed and documented.

Premises

Our distribution sites are designed, located, constructed, and maintained to be suitable for the intended operations, offering protection from contamination, unauthorized access, and environmental extremes.

The layout facilitates logical movement and segregation, preventing mix-ups and cross-contamination. Dedicated, secured areas are provided for Quarantine, Rejected, Recalled, and Returned products.

Access is restricted to authorized personnel. Appropriate security measures are in place to prevent theft or unauthorized handling of products.

Premises are maintained to a high standard of cleanliness, with documented sanitation programs.

Heating, Ventilation and Air Conditioning System (HVAC)

•Our storage facilities maintain environmental conditions (temperature, humidity) as required by the product specifications and regulatory guidelines.

•The HVAC system (or equivalent climate control) is qualified/validated and subject to regular maintenance and calibration.

•Continuous Monitoring: Critical storage areas are equipped with validated, continuous temperature mapping and monitoring systems with alarm functions to alert personnel of excursions.

Equipment

All equipment critical to the storage and distribution of medicinal products is appropriately qualified, calibrated, and maintained.

•Calibration: Measuring equipment (e.g., thermometers, hygrometers, freezers, weighing scales) is calibrated against traceable standards on a defined schedule.

•Maintenance: A documented preventative maintenance program is in place for all critical equipment, including refrigeration units and alarm systems.

Cleaning and Sanitation

Detailed SOPs govern the cleaning and sanitation of the premises and equipment to prevent contamination, residue build-up, and pest infestation.

•Cleaning Agents: Approved cleaning and disinfectant agents are used, and the effectiveness of cleaning procedures is monitored.

•Pest Control: A documented, contract-managed pest control program is in place, covering all areas of the site.

Documentation

A robust documentation system is the foundation of our QMS. All documents are accurate, legible, complete, and readily available.

•Types: Documentation includes SOPs, Work Instructions, Specifications,

Master Batch Records (if applicable), Training Records,

Qualification/Validation Protocols and Reports, Maintenance Logs, and Distribution Records.

•Control: Documents are formally issued, revised, and archived under Change Control. Only the current, authorized versions are in use.

•Retention: All records are retained for a period specified by regulatory requirements (typically $5$ years) and are protected from loss or damage.

Product Management and Warehousing

Our warehousing procedures are designed to protect the integrity of the medicinal products throughout their storage life.

The storing procedure is carried out as follows:

•Goods Receipt: Products are checked upon receipt against the purchase order and delivery note for accuracy, integrity, and regulatory status. Any discrepancies or damage are documented.

•Temperature Checks: Temperature-sensitive products are immediately moved to their required storage conditions (e.g., refrigeration or ambient).

•First-Expiry, First-Out (FEFO): Products are managed using the FEFO principle to minimize the risk of distributing expired stock.

•Segregation: Physical or electronic segregation is maintained between different stock statuses (e.g., Sellable, Quarantine, Rejected, Recalled).

Quarantine and storage of finished packaged products

•Quarantine: All incoming products are initially placed under Quarantine status (physically or electronically) until formally released by the QP/QA.

•Sellable Storage: Released products are stored in designated areas under controlled environmental conditions, continuously monitored.

Quality Control (QC)

While the Company’s primary activity is distribution, effective QC oversight is crucial.

•Batch Verification: The QC function is responsible for ensuring the accuracy of batch numbers, expiry dates, and product identity during all handling stages.

•Sampling & Testing (if applicable): If the site performs any required QC activities (e.g., re-testing of bulk product, quality checks on labeling), these are carried out according to documented, validated procedures in a suitable facility (either in-house or via a qualified contract lab).

•Stability Monitoring: Products requiring in-market stability data are monitored in collaboration with the manufacturer.

Distribution

We ensure that medicinal products are delivered to the correct recipient within a satisfactory time frame and under the required storage conditions.

Transportation is contracted out to qualified, approved carriers. Quality Agreements define the responsibilities for maintaining product quality and security during transit.

For temperature-sensitive products, validated passive or active cooling/thermal packaging systems are used, and transit temperature is monitored and recorded.

We operate a dedicated system for the prompt and thorough handling of qualityrelated issues.

We maintain a documented, rapid, and effective Recall Procedure that can be activated immediately, ensuring that affected products are identified and removed from the supply chain (including from clients) quickly. Recalls are performed in collaboration with the manufacturer and regulatory authority.

Self-Inspection

The Company conducts Self-Inspections (internal audits) according to an approved, defined schedule.